Scope of Work

• Deep water wells.

• Water Hammer System.

• Aeration Towers and Detention Reservoirs.

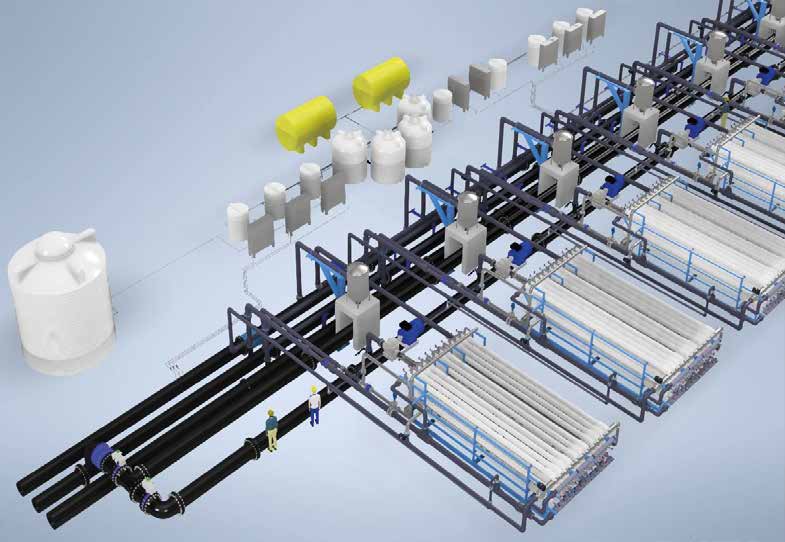

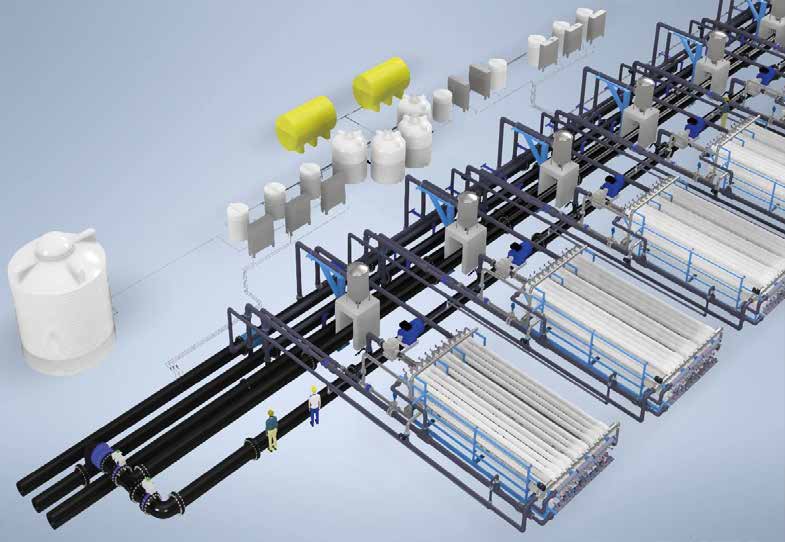

• Flat Sheet Ceramic Membranes Filters.

• RO System (Reverse Osmosis).

• Drinking Water Reservoirs 50.000 m3.

• Transformer Building (2@33KV/4.16 KV@14

MV&2@4.16KV/400V@5MV).

• Switch Gear Panels Z1 -33 KV & Z2 and Z3-1.16 KV.

• Instrumentation, Control and SCADA System.

• Low Voltage Panels, MCC Panels and Lighting System.

• Earthling, Lightning and Fire Alarm System.

• Potable Water Transmission Line.

• Administration Building.

• Guard House.

Introduction

• The project concems on A1-Homaimah Water Station Expansion, capacity of water 50,000 m3/day, located at A1-Homaimah, Hai’l.

• The raw water is water and the treatment pratess is reverse osmosis desalination.

• The raw water for desalination is collected from twenty (20) wells, each one considered stable capacity of 220 m3/h. Thus the total design flow is 4,4m m3/h.

• All water transfer pipes are ductile cast iron, intemally lined with cement mortar. Borehole raw water temgErature, affecting the viscosity of water, is 28 ˚c.

• The water coming from wells enters directly the æration tower (radon and iron removal) then detention tank (pretreatment) and ceramic flat sheet membrane tanks (filtration and radium removal)

• The pump station of ceramic filter building includes nine centrifugal pumps, six of

them dedicated to feed reverse osmosis trains. Each pump provide the feed water for two (2) RO trains, thus four pumps are on duty while there are two as spares.

• The capacity of each pump is 625 m3/h at 3 bars, thus the flow in each RO feed pipe is 312 m3/h.

• The chemicals dosing systems at ceramic filter building includes the following systems:

• Preparation and dosing of HMO slurry

• Chemicals for cleaning in place (CIP) of ceramic filters

• Create two (2) groups of RO trains, i.e. a first group of four (4) trains and a secondone of four (4) trains as well.

Each group of four (4) trains has common feed water pipe line, common dosing devices and common monitoring for pre-treatment as well.

• Post-treatment is applied for the total permeate of eight (8) RO trains, before drinking water storage tanks.

• Permeate water collect in two drinking water storage reservoir capacity 100,000 m3.

• City pump station including 10 water pumps (8 duty +2 standby) 500 m3/hr

• Total water pumping to Hail city 100,000 m3/ day through water transmission Line size 1000 mm diameter, 57 km from tie city

Gallery

Key Benefits

Due to Saudi Arabia’s scarce water resources, and the rising demand between the supply and demand

of water, The National Water Company (NWC) has launched Al Homayma Water Station Expansion

100,000 m3/day project in the city of Hail, to construct a Reverse Osmosis Desalination Plant with a

capacity of 200.000 m3/day to produce water with potable standards for purposes to serve the city and

a citizens of more than 935.000 residents.

Arab contractors company (ACC) was awarded the project and hand over to AEICO on its extensive

engineering experience with developing desalination projects and its world class quality process design,

construction, operation and maintenance of plants utilizing the Reverse Osmosis Technology.

Process Description

Due to Saudi Arabia’s scarce water resources and the increasing gap between water supply and demand, the National Water Company (NWC) has launched the Al Homayma Water Station Expansion project in the city of Hail. The project, with a capacity of 100,000 m³/day, involves the construction of a Reverse Osmosis (RO) Desalination Plant with a total production capacity of 200,000 m³/day to provide potable water that meets drinking standards, serving more than 935,000 residents of the city. The Arab Contractors Company (ACC) was awarded the project, which was then handed over to AEICO in recognition of its extensive engineering expertise in developing desalination projects, as well as its world-class quality in process design, construction, operation, and maintenance of plants utilizing Reverse Osmosis Technology.